|

Applicable vehicle type |

Universal |

|

Capacity |

33''inch |

|

Min height |

154mm |

|

Max height |

700mm |

|

Gross weight |

14kg |

|

Net weight |

13kg |

|

Material |

High strength steel |

|

Processing capacity |

High strength, high precision machining and forming |

|

Suitable |

Small to medium garage |

OY1233 33inch Farm Jack

The bottom side, with thickened triangular support, makes the carrying capacity stronger and the structure more solid. Mechanical press bar coupled with human design ergonomics makes lifting easier and less labor intensive.

Get A Quote

About

Jiaxing Ouya Machinery Manufacturing Co., Ltd.

Jiaxing Ouya Machinery Manufacturing Co., Ltd. is a manufacturer specializing in the production of various hydraulic machinery and tools. Is China OY1233 33inch Farm Jack Suppliers and Custom OY1233 33inch Farm Jack Manufacturers. We are committed to the research, design and manufacturing of high-quality tools, including auto repair equipment and tools, garage tools, motorcycle repair tools, etc. Excellent quality, innovative structure and easy operation. Ouya Machinery has passed ISO9001 quality system certification, and some products have obtained CE certification. Our products are warmly welcomed in international markets such as Europe, the United States, Canada, Australia, Japan, and Southeast Asia.

We have always adopted high-quality technology, designed and developed high-quality, novel products, provided excellent services, established a good corporate image, and won praise from the industry and customers. Jiaxing Ouya Machinery Manufacturing Co., Ltd. is located in the center of Jiaxing, Zhejiang Province, about an hour's drive from Shanghai and Hangzhou. It is close to the Hangzhou Bay Cross-sea Bridge and has very convenient sea, land and air transportation. Welcome friends at home and abroad to visit us. We will be your choice and look forward to success together with you.

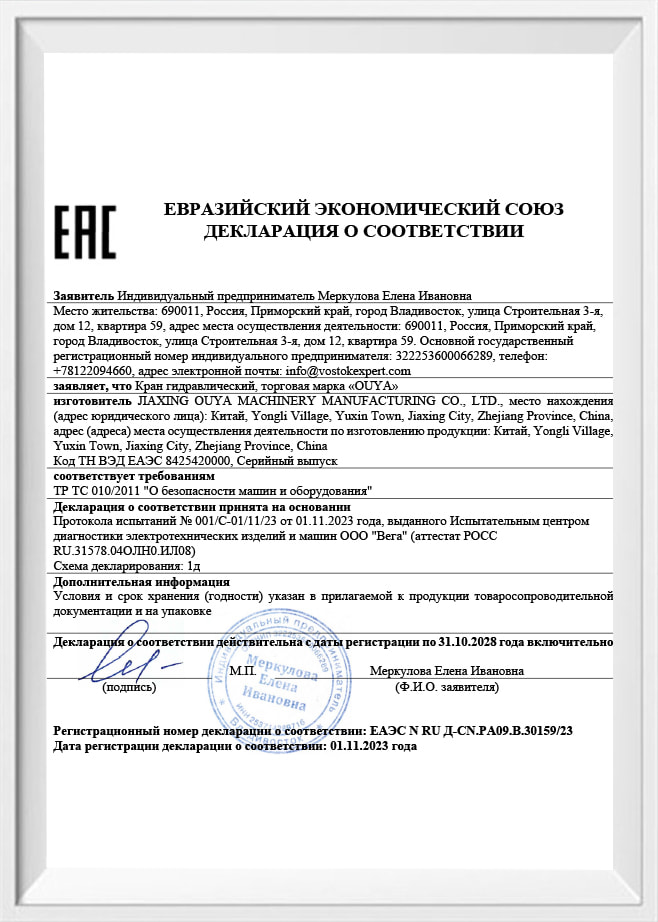

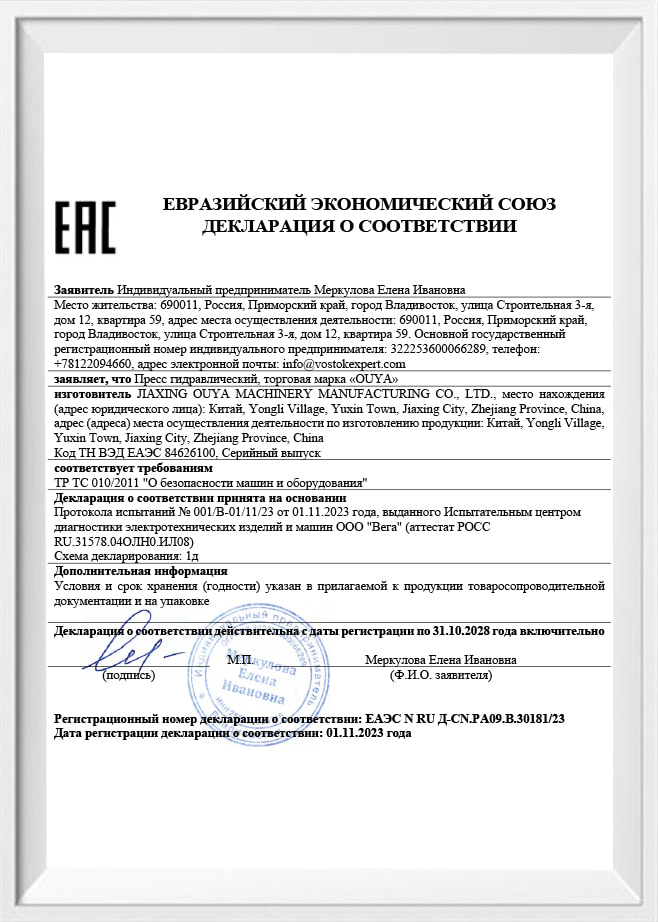

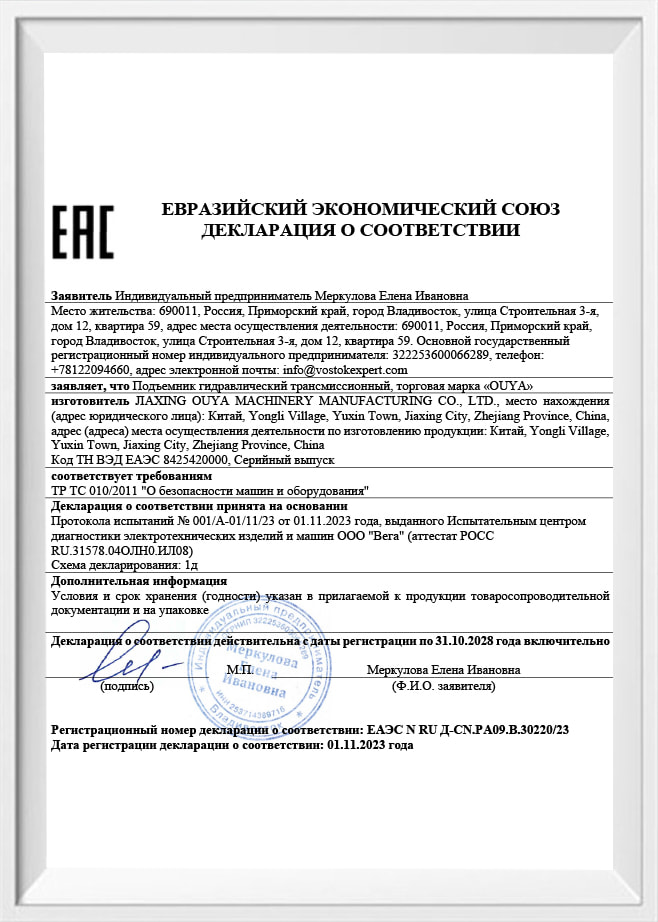

Certificate Of Honor

News

Industry Knowledge

How to properly operate the OY1233 33-inch farm jack for heavy lifting?

1. Preparation stage

Before using the OY1233 33-inch farm jack for heavy lifting, you must ensure that all preparations are adequate and safe. First, check whether the appearance of the jack is intact and whether there are any obvious damages or cracks. Secondly, check whether the hydraulic system of the jack is leaking or has other abnormalities. Next, confirm whether the load-bearing capacity of the jack meets the weight of the object to be lifted. Finally, prepare personal protective equipment such as hard hats, gloves, and safety shoes, and ensure that safety warning signs in the work area are in place.

2. Install the jack

Before installation, check that the jack is in good condition, especially the hydraulic system and load-bearing parts, to ensure there are no cracks, leaks or other damage. Choose a flat, hard and stable ground as the installation point, avoid installing on soft soil, slippery or uneven ground to ensure that the jack will not slide or tilt during use. Prepare the tools and materials required for installation, such as wrenches, screwdrivers, support rods, brackets, etc. Place the jack smoothly on the selected installation site, ensuring that its base is in full contact with the ground and remains stable. Use support rods or brackets to adjust the height and stability of the jack according to actual needs. Make sure the support pole or bracket is securely installed to prevent shaking or tilting during use. Connect the hydraulic system of the jack to the operating handle or foot switch to ensure that the connection is firm and reliable and there is no leakage. Ensure that the safety valve of the jack works properly and can automatically release pressure in the event of overload or abnormal conditions to ensure safe operation. After installation is complete, shake the jack gently to check whether it is stable and make sure there is no shaking or tilting. Open the hydraulic valve and observe whether the hydraulic system is working properly and whether there is leakage or abnormal noise. Before formal use, you can conduct a test run and raise and lower the jack several times to check its working performance and stability.

3. Operating the jack

Open the hydraulic valve of the jack and ensure that the hydraulic system is in normal working condition. Insert the lifting rod of the jack into a suitable position under the weight to ensure that the lifting rod contacts the weight smoothly and does not damage the surface of the weight. Slowly operate the hydraulic control handle to gradually raise the lifting rod of the jack until the weight is lifted to the required height. During the lifting process, pay close attention to the state of the heavy object and the working condition of the jack to ensure smooth and safe operation. When the weight is lifted to the predetermined position, close the hydraulic valve and lock the lifting rod of the jack to prevent the weight from falling.

4. Precautions

During operation, it is strictly prohibited to use the jack with overload to avoid damage to the jack or safety accidents. When operating the jack, you should maintain smooth and slow movements to avoid rapid lifting and lowering that may cause heavy objects to shake or lose control of the jack. When using a jack to lift heavy objects, make sure that no one is standing or passing by the heavy objects to avoid accidental injuries. Regularly inspect the jack's hydraulic system and structural components to ensure they are in good working order. If any abnormality is found, stop using it immediately and carry out repairs.

5. Follow-up processing

After the weight is lifted to the predetermined position and the related work is completed, the correct steps need to be followed to lower the jack and weight safely. Open the hydraulic valve and slowly operate the hydraulic control handle to gradually lower the lifting rod of the jack. During the descent process, it is also necessary to pay close attention to the state of the heavy object and the working condition of the jack to ensure smooth and safe operation. When the weight is completely lowered, remove the lifting rod of the jack from under the weight and close the hydraulic valve. Check whether the jack is in good condition. If it is damaged or abnormal, repair or replace it in time. Clean the work area, ensure all tools and equipment are in their proper places, and keep the workplace tidy and safe.

What are the advantages and disadvantages of the OY1233 33-inch farm jack compared to other brands of farm jacks?

advantage analysis

Strong load-bearing capacity: The OY1233 33-inch farm jack is precision designed and rigorously tested to withstand extreme weight pressure without deformation or damage. This strong load-bearing capacity not only ensures the safety of the operation, but also improves the efficiency of the operation. In daily farm work, whether it is repairing agricultural machinery, changing tires, or other scenarios that require lifting heavy objects, this jack can easily handle it, providing great convenience to farmers and operators. The strong load-bearing capacity also means this jack has a longer service life. It can maintain stable performance under long-term, high-intensity use, reducing the cost and time consumption caused by frequent replacement of jacks. Therefore, for farmers, choosing the OY1233 33-inch farm jack not only means obtaining strong load-bearing capacity, but also achieving higher economic benefits.

Stable and reliable structural design: This jack is made of strong and durable materials, with a stable structure and not easy to deform. The bottom is designed with a wide support surface to ensure that it is not easy to slide or tilt during use, thus improving the safety of the operation.

Easy to operate: The operation of the OY1233 33-inch farm jack is relatively simple, even inexperienced workers can get started quickly. In addition, its handle design conforms to ergonomic principles, making it more comfortable to use and reducing fatigue caused by long-term work.

Wide range of applications: This jack is not only suitable for farm operations, but also can be used in other situations where heavy objects need to be lifted. Its 33-inch size allows for greater flexibility when handling large equipment or items.

High cost performance: Compared with some high-end brand jacks, the OY1233 33-inch farm jack has a price advantage. It provides good performance and quality while maintaining a relatively reasonable price, allowing more farmers and operators to choose to use it.

Weakness analysis

Relatively low brand awareness: Compared with jacks from some well-known international brands, the brand awareness of the OY1233 33-inch farm jack may be low. This may cause some consumers to have doubts about its quality and performance when purchasing and choose other, more well-known brands.

The after-sales service system needs to be improved: At present, the after-sales service system of the OY1233 33-inch farm jack may not be perfect enough. Some consumers report that it is difficult to obtain timely and effective solutions when they encounter problems after purchasing. This may affect consumers' purchasing confidence and usage experience.

Insufficient use of innovative technology: In terms of material application, although the jack uses strong and durable materials, it does not use some new high-performance materials that may have better load-bearing capacity and longer service life. In terms of intelligence, there are currently some jacks with intelligent control functions on the market, which can achieve more precise lifting operations through sensors and control systems, and provide safety protection mechanisms. However, the OY1233 33-inch farm jack has not made a significant breakthrough in this regard and is still stuck in the traditional mechanical operation stage. In terms of energy conservation and environmental protection, new technologies can also help jacks reduce energy consumption and emissions. However, the OY1233 33-inch farm jack has not been significantly optimized in this regard, and there may be certain energy waste and environmental pollution issues.

Product types and specifications are relatively single: At present, the OY1233 brand may mainly focus on the production and sales of the 33-inch farm jack, and the product types and specifications are relatively single. This may limit its application scope in different operating scenarios and needs, making it difficult for users with special needs to find suitable products.

English

English Español

Español Deutsche

Deutsche