-

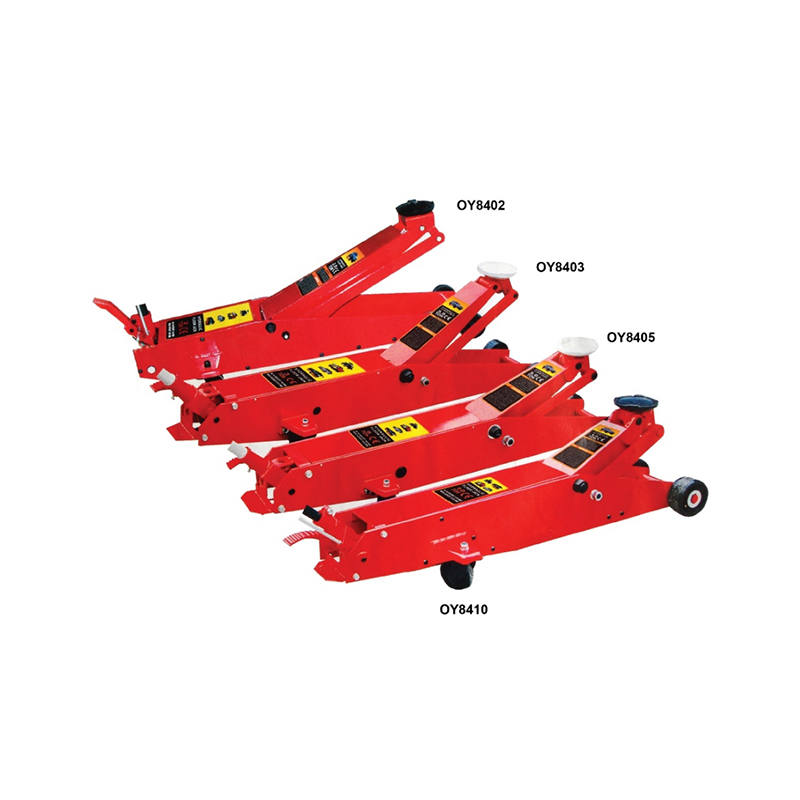

Long air floor jack

OY8402 2ton Hydraulic Long Floor Jack For Car Repairing With CEThe use of thickened steel plates and thick lifting arms make this machine very stable and it has a long service life. Enhanced pump body is used to make it more reliable in terms of pressure performance. Very easy to operate, you can easily lift the vehicle, saving time and effort, and lifting is very stable.

VIEW MORE -

Long air floor jack

OY8403 3ton Hydraulic&air Long Floor JackThe 3-ton weight capacity can meet the lifting needs of most vehicles. High-quality thickened steel plate, reasonable structural design, the overall stability can be very good, strong load-bearing capacity. The whole tool is very small and won't take up a lot of space, making it a good helper for changing tires and solving travel worries.

VIEW MORE -

Long air floor jack

OY8405 Car Lifting Hydraulic Long Floor Jack With CEThe five-ton capacity is large enough to meet the tire-changing lifting needs of most vehicles. The pump is well sealed and not easy to leak oil. With a rotatable tray for precise positioning and flexible operation. It is an essential tire-changing tool for driving out and about, and is a powerful and stable companion.

VIEW MORE -

Long air floor jack

OY8410 Hydraulic Long Floor Jack With CEThe OY8410 hydraulic lengthy arm jack comes with CE certification and is a professionally designed, first-rate product. Its long arm layout makes operation extra handy and appropriate for various car repair and renovation work. Made of great materials for superior sturdiness and balance.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY102A 2000kg Hydraulic Bottle Jack For GarageWith a lifting capacity of 2 tons, this powerful jack is a must-have tool for repairing cars or hobbyist DIY. It is equipped with a hydraulic pump that can lift and lower objects using oil pressure. The safety valve is equipped with a safety performance of this jack.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY112A 12000kg Hydraulic Bottle JackThe OY112A 12000kg hydraulic jack is a good and dependable device with the benefit of robust load-bearing potential and may easily handle numerous heavy-obligation motors. It adopts advanced hydraulic technology to provide stable lifting characteristic, easy operation, safety and reliability.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY106A 6ton HYdraulic Bottle Jack With CE For Medium GarageThis hydraulic bottle jack has CE certification and is a great quality product with a good reputation. It has a 6-ton capacity, which is good for most needs in repairing cars. If you need jacks with other weight capacity specifications, our jack capacity specifications cover 2 tons to 50 tons.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY104A 4000kg portable Hydraulic Bottle JackWith a lifting capacity of 4 tons, this powerful jack is a great and essential companion in the process of car repair. It can lift and lower objects using oil pressure. Obviously, this one is much safer compared to jacks that are not equipped with a safety valve.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY116A 16ton Hydraulic Bottle Jack With CEThe OY116A 16-ton hydraulic jack is made from strong and sturdy materials, capable of withstanding weights as much as 16 heaps, and is suitable for numerous automobiles and business situations. The roof has an splendid hydraulic device, providing strong lifting feature and smooth operation.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY120A 20ton Hydraulic Bottle Jack With High QualityThe OY120A 20-ton hydraulic jack is manufactured from high-strength metal and is solid and durable. The lifting peak is 145mm, the adjustment top is 60mm, and the weight is 12kg. Using high-electricity, high-precision processing era, it's far appropriate to be used in small to medium-sized garages. The product is properly designed, easy to operate and quite reliable, and is extensively used in automobile preservation and different fields.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY110A 10ton Hydraulic Bottle Jack With CEThe OY110A 10-ton hydraulic bottle jack has CE certification and is a extraordinary product. Its principal frame is constructed of strong metallic with excessive load-bearing capability, making it appropriate for a whole lot of car protection and commercial packages. Flexible operability, easy to use in small areas

VIEW MORE -

Hydraulic bottle jack with safety valve

OY130A 30ton Hot Sale Hydraulic Bottle JackOY130A 30ton Hot Sale Hydraulic Bottle Jack adopts remarkable hydraulic system and may effortlessly undergo loads as much as 30 tons. Features strong structure and durable substances ensuring secure and dependable operation. The product layout is compact, easy to hold and store, and can be broadly used in vehicle preservation, creation engineering and different fields.

VIEW MORE

Product Category

Excellent product with exquisite craftsmanship

ABOUT

OUYA MACHINERY

Professional custom car hydraulic press machine and car hydraulic machinery tools

. We are committed to the research, design and manufacturing of high-quality tools, including auto repair equipment and tools, garage tools, motorcycle repair tools, etc.

-

0

Founded In

-

0+

Factory area

-

0+

Technical Staff

OUR

ADVANTAGES

Ever since its establishment, OUYA has never stopped walking inpursuit of quality. Custom car hydraulic press machine and car hydraulic machinery tools

MORE

LATEST NEWS

Our factory have got experience and strong technology in producing autorepair tools and equipment in many years. we have skilled workers and strictmanagement for meeting customers'demands.

-

06/12 2025

How does Hydraulic Compact Pipe Bender help pipe processing in automobile manufacturing?

Analysis of the working principle of hydraulic compact pipe bender Hydraulic Compact Pipe Bender mainly relies on the hydraulic system to generate strong press...

-

06/05 2025

How practical is the 48-inch Farm Jack For Off-road?

From a mechanical point of view, it cleverly uses the principle of levers. Through a carefully designed lever system, the operator can generate a strong lifting...

-

05/29 2025

How does a portable car power jack solve common problems in vehicle use?

In the daily use of cars, various emergencies always come unexpectedly, causing many troubles for car owners. Whether it is accidental damage to the tire, or th...

-

05/22 2025

Why can Hydraulic Lifting Table Cart significantly improve handling efficiency?

1. Limitations of traditional handling methodsIn traditional handling methods, operators usually need to use force to carry heavy objects, or rely on manual pus...

English

English Español

Español Deutsch

Deutsch