-

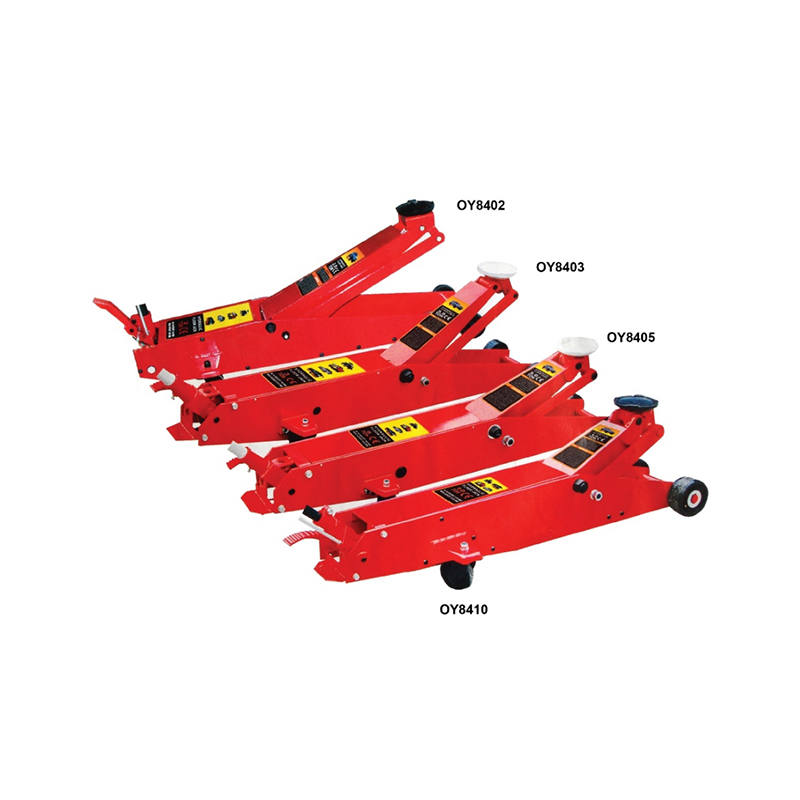

Long air floor jack

OY8402 2ton Hydraulic Long Floor Jack For Car Repairing With CEThe use of thickened steel plates and thick lifting arms make this machine very stable and it has a long service life. Enhanced pump body is used to make it more reliable in terms of pressure performance. Very easy to operate, you can easily lift the vehicle, saving time and effort, and lifting is very stable.

VIEW MORE -

Long air floor jack

OY8403 3ton Hydraulic&air Long Floor JackThe 3-ton weight capacity can meet the lifting needs of most vehicles. High-quality thickened steel plate, reasonable structural design, the overall stability can be very good, strong load-bearing capacity. The whole tool is very small and won't take up a lot of space, making it a good helper for changing tires and solving travel worries.

VIEW MORE -

Long air floor jack

OY8405 Car Lifting Hydraulic Long Floor Jack With CEThe five-ton capacity is large enough to meet the tire-changing lifting needs of most vehicles. The pump is well sealed and not easy to leak oil. With a rotatable tray for precise positioning and flexible operation. It is an essential tire-changing tool for driving out and about, and is a powerful and stable companion.

VIEW MORE -

Long air floor jack

OY8410 Hydraulic Long Floor Jack With CEThe OY8410 hydraulic lengthy arm jack comes with CE certification and is a professionally designed, first-rate product. Its long arm layout makes operation extra handy and appropriate for various car repair and renovation work. Made of great materials for superior sturdiness and balance.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY102A 2000kg Hydraulic Bottle Jack For GarageWith a lifting capacity of 2 tons, this powerful jack is a must-have tool for repairing cars or hobbyist DIY. It is equipped with a hydraulic pump that can lift and lower objects using oil pressure. The safety valve is equipped with a safety performance of this jack.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY112A 12000kg Hydraulic Bottle JackThe OY112A 12000kg hydraulic jack is a good and dependable device with the benefit of robust load-bearing potential and may easily handle numerous heavy-obligation motors. It adopts advanced hydraulic technology to provide stable lifting characteristic, easy operation, safety and reliability.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY106A 6ton HYdraulic Bottle Jack With CE For Medium GarageThis hydraulic bottle jack has CE certification and is a great quality product with a good reputation. It has a 6-ton capacity, which is good for most needs in repairing cars. If you need jacks with other weight capacity specifications, our jack capacity specifications cover 2 tons to 50 tons.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY104A 4000kg portable Hydraulic Bottle JackWith a lifting capacity of 4 tons, this powerful jack is a great and essential companion in the process of car repair. It can lift and lower objects using oil pressure. Obviously, this one is much safer compared to jacks that are not equipped with a safety valve.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY116A 16ton Hydraulic Bottle Jack With CEThe OY116A 16-ton hydraulic jack is made from strong and sturdy materials, capable of withstanding weights as much as 16 heaps, and is suitable for numerous automobiles and business situations. The roof has an splendid hydraulic device, providing strong lifting feature and smooth operation.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY120A 20ton Hydraulic Bottle Jack With High QualityThe OY120A 20-ton hydraulic jack is manufactured from high-strength metal and is solid and durable. The lifting peak is 145mm, the adjustment top is 60mm, and the weight is 12kg. Using high-electricity, high-precision processing era, it's far appropriate to be used in small to medium-sized garages. The product is properly designed, easy to operate and quite reliable, and is extensively used in automobile preservation and different fields.

VIEW MORE -

Hydraulic bottle jack with safety valve

OY110A 10ton Hydraulic Bottle Jack With CEThe OY110A 10-ton hydraulic bottle jack has CE certification and is a extraordinary product. Its principal frame is constructed of strong metallic with excessive load-bearing capability, making it appropriate for a whole lot of car protection and commercial packages. Flexible operability, easy to use in small areas

VIEW MORE -

Hydraulic bottle jack with safety valve

OY130A 30ton Hot Sale Hydraulic Bottle JackOY130A 30ton Hot Sale Hydraulic Bottle Jack adopts remarkable hydraulic system and may effortlessly undergo loads as much as 30 tons. Features strong structure and durable substances ensuring secure and dependable operation. The product layout is compact, easy to hold and store, and can be broadly used in vehicle preservation, creation engineering and different fields.

VIEW MORE

Product Category

Excellent product with exquisite craftsmanship

ABOUT

OUYA MACHINERY

Professional custom car hydraulic press machine and car hydraulic machinery tools

. We are committed to the research, design and manufacturing of high-quality tools, including auto repair equipment and tools, garage tools, motorcycle repair tools, etc.

-

0

Founded In

-

0+

Factory area

-

0+

Technical Staff

OUR

ADVANTAGES

Ever since its establishment, OUYA has never stopped walking inpursuit of quality. Custom car hydraulic press machine and car hydraulic machinery tools

MORE

LATEST NEWS

Our factory have got experience and strong technology in producing autorepair tools and equipment in many years. we have skilled workers and strictmanagement for meeting customers'demands.

-

09/19 2024

1. Application of green materials1. Selection of environmentally friendly materialsAuto Repair Equipment manufacturers are increasingly inclined to use environm...

In terms of environmental protection and energy saving, what are the new development directions of auto repair equipment?

1. Application of green materials1. Selection of environmentally friendly materialsAuto Repair Equipment manufacturers are increasingly inclined to use environmentally friendly materials, such as recyclable metals, bio-based plastics, etc., to reduce pollution to the environment. These materials have low energy consumption and low emissions during the production process, and can be more easily recycled and reused after the equipment is discarded, reducing the environmental impact of the entire life cycle. 2. Reduction of low volatile organic compounds (VOC)In the process of automobile repair, the use of chemicals such as cleaning agents and lubricants is inevitable. However, traditional products often contain high VOCs, which pose a threat to the environment and human health. Therefore, modern auto repair equipment has begun to use low-VOC or VOC-free environmentally friendly cleaning agents and lubricants to reduce air pollution and protect the health of maintenance personnel. 2. Integration of energy-saving technologies1. High-efficiency motors and power systemsMany Auto Repair Equipment, such as lifts, tire changers, etc., use high-efficiency motors and advanced power systems. These systems can significantly reduce energy consumption and improve energy efficiency while ensuring equipment performance. For example, some high-end lifts use variable frequency drive technology, which can automatically adjust the motor speed and power output according to the load conditions to achieve energy saving and consumption reduction. 2. Intelligent energy-saving control systemWith the development of the Internet of Things and intelligent control technology, Auto Repair Equipment has also begun to be equipped with intelligent energy-saving control systems. These systems can monitor the operating status and energy consumption of the equipment in real time, and reduce energy consumption by optimizing control strategies. For example, when the equipment is idle, it automatically enters sleep mode to reduce unnecessary power consumption; when the load is light, the motor speed and output power are reduced. III. Resource recycling and waste management1. Recycling and reuse of waste equipmentAuto Repair Equipment is often treated as waste after reaching its service life. However, many parts and materials in waste equipment still have reuse value. Therefore, some manufacturers have begun to establish a waste equipment recycling system to disassemble, sort and reuse waste equipment. This can not only reduce the amount of waste generated, but also save raw materials and energy. 2. Waste management during maintenanceDuring the process of automobile maintenance, a large amount of waste oil, waste liquid and waste parts will be generated. In order to reduce the pollution of these wastes to the environment, modern automobile maintenance equipment has begun to pay attention to waste management. For example, it is equipped with a waste oil collection and treatment system to purify the waste oil for reuse or safe disposal; the waste parts are classified for recycling and reuse, etc. IV. Compliance and improvement of environmental protection standards1. Compliance with international environmental protection standardsWith the improvement of global environmental awareness, countries have formulated strict environmental protection standards and regulations. Automobile maintenance equipment manufacturers need to follow these standards to design and produce products. For example, the EU's RoHS directive restricts the use of certain hazardous substances in electronic equipment; China's "Environmental Protection Law" also puts forward clear requirements for the environmental protection behavior of enterprises. 2. Continuous innovation of environmental protection technologyIn order to continuously improve the environmental performance and market competitiveness of products, automobile maintenance equipment manufacturers need to continue to carry out technological innovation and research and development. For example, develop more efficient, energy-saving and environmentally friendly maintenance equipment and processes; research new environmentally friendly materials and chemicals, etc. These innovative achievements will promote the development of the automobile maintenance equipment industry in a more green and sustainable direction. In terms of environmental protection and energy saving, automobile maintenance equipment is moving towards the application of green materials, the integration of energy-saving technologies, resource recycling and waste management, and compliance with and improvement of environmental protection standards. These new development directions will not only help reduce the pollution and damage to the environment caused by the auto repair industry, but also help promote the sustainable development of the entire industry.

-

09/12 2024

With the rapid development of science and technology, intelligent inventory management, artificial intelligence (AI) and big data technologies are increasingly ...

Auto Repair Equipment: Innovative Application of Intelligent Inventory Management and Artificial Intelligence Big Data Technology

With the rapid development of science and technology, intelligent inventory management, artificial intelligence (AI) and big data technologies are increasingly widely used in various industries, and the field of auto repair equipment is no exception. The application of these technologies not only improves maintenance efficiency, but also optimizes inventory management, bringing unprecedented changes to Auto Repair Equipment. Intelligent Inventory Management: Improving Efficiency and AccuracyTraditional auto repair equipment inventory management has many pain points, such as low efficiency, difficult management, and high costs. These problems often lead to inventory backlogs or shortages, affecting repair progress and customer satisfaction. The intelligent inventory management system achieves accurate prediction and real-time management of inventory by introducing big data analysis and AI algorithms. The intelligent inventory management system can use historical sales data and market demand forecasting models to accurately predict the demand for various types of repair equipment in the future. This forecast is based on big data analysis, taking into account multiple factors such as seasonal trends, vehicle ownership, and failure rates, ensuring the accuracy and reliability of the forecast results. The system can automatically adjust inventory levels based on the forecast results to avoid excessive inventory or out-of-stock phenomena. When the inventory level is lower than the safety threshold, the system will automatically trigger a replenishment order to ensure timely replenishment of inventory. At the same time, the system can also optimize the procurement process, automatically select cost-effective suppliers, and reduce procurement costs. The intelligent inventory management system also realizes barcode management and full traceability of inventory equipment. Each piece of equipment is attached with a unique barcode label, and the entire process from entry to exit, return, transfer and inventory can be completed by scanning the code. This not only improves work efficiency, but also ensures the accuracy and real-time nature of inventory data. Application of artificial intelligence and big data technology in automobile maintenance equipmentThe application of artificial intelligence and big data technology in automobile maintenance equipment is mainly reflected in fault diagnosis, predictive maintenance, parts management and customer service. Fault diagnosis and predictive maintenanceAI technology can monitor the operating status of automobile maintenance equipment in real time, predict potential faults and perform maintenance in advance through data collection and analysis. For example, sensors can collect equipment operating data, such as temperature, vibration, current, etc., and transmit these data to the cloud for analysis. AI algorithms use these data to establish fault diagnosis models, which can quickly identify faults and give maintenance suggestions. Predictive maintenance uses big data analysis and machine learning technology to predict the possibility and time of potential failures by analyzing historical maintenance records, equipment operating status and environmental factors. This helps maintenance companies to formulate maintenance plans in advance and avoid downtime and increased maintenance costs caused by sudden equipment failures. Parts ManagementAI and big data technologies also play an important role in the management of Auto Repair Equipment parts. The intelligent inventory management system can optimize inventory levels and reduce inventory costs based on demand forecasting models. At the same time, AI technology can also help companies automatically identify parts suppliers, optimize procurement processes and improve procurement efficiency. In addition, AI can also analyze parts production process data, identify potential quality problems and improve parts quality. Customer ServiceAI technology also optimizes the customer service experience of Auto Repair Equipment. Intelligent customer service based on a dialogue system can help customers quickly obtain information such as maintenance appointments and troubleshooting. At the same time, AI can also provide personalized maintenance suggestions and services by collecting customer data and analyzing customer behavior, thereby improving customer satisfaction and loyalty. The application of intelligent inventory management and artificial intelligence and big data technologies in auto repair equipment not only improves maintenance efficiency and accuracy, but also optimizes inventory management and customer service. The application of these technologies has brought unprecedented changes and development opportunities to the auto repair industry. With the continuous advancement of technology and the expansion of application scenarios, I believe that automobile maintenance equipment will become more intelligent and efficient in the future, injecting new impetus into the development of the industry.

-

09/05 2024

In the field of automobile repair, with the rapid development of technology, Auto Repair Equipment is experiencing unprecedented technological innovation. These...

What technological innovations in the latest Auto Repair Equipment can significantly improve the efficiency and accuracy of automobile repairs?

In the field of automobile repair, with the rapid development of technology, Auto Repair Equipment is experiencing unprecedented technological innovation. These innovations not only greatly improve the efficiency and accuracy of maintenance, but also promote the intelligence and modernization of the entire industry. 1. Intelligent diagnostic systemThe intelligent diagnostic system is one of the most eye-catching technological innovations in Auto Repair Equipment in recent years. These systems utilize artificial intelligence (AI) and big data analysis technology to quickly and accurately read vehicle fault codes and provide detailed fault analysis and repair recommendations. For example, by connecting the OBD-II interface of the vehicle, intelligent diagnostic tools can monitor vehicle performance parameters in real time, combine historical data and fault case libraries, quickly locate the problem, and provide the optimal maintenance plan. This intelligent diagnosis method not only shortens troubleshooting time, but also improves the accuracy and reliability of diagnosis. 2. Automated maintenance robotAutomated maintenance robots are another important technological innovation point. These robots integrate advanced sensors, actuators and control systems and are capable of performing a range of complex maintenance tasks, such as welding, painting, parts assembly, etc. Through precise program control, they can complete maintenance work with high precision and efficiency, reducing errors and uncertainties caused by human operations. At the same time, automated maintenance robots also have the ability to learn and optimize themselves, and can continuously accumulate maintenance experience and improve maintenance quality and efficiency. 3. 3D printing technologyThree-dimensional printing technology is increasingly used in the field of Auto Repair Equipment. This technology enables the rapid manufacture of complex parts, especially those that are difficult to find or cost prohibitive to replace. By obtaining the 3D model of the part through 3D scanning and then printing it using a 3D printer, the repair shop can obtain the required parts in a short time, greatly shortening the maintenance cycle. In addition, 3D printing technology can also achieve personalized customization to meet special maintenance needs and improve the flexibility and adaptability of maintenance. 4. Internet of Things (IoT) and Internet of Vehicles TechnologyThe integration of Internet of Things and Internet of Vehicles technologies brings new possibilities to car maintenance. Through on-board sensors and wireless communication networks, vehicles can transmit operating data to the maintenance center in real time, including engine status, fuel consumption, fault warning, etc. The maintenance center can remotely monitor the status of the vehicle, detect potential problems in advance, and formulate corresponding maintenance plans. This type of predictive maintenance not only reduces the incidence of failures, but also improves vehicle safety and reliability. At the same time, IoT technology can also optimize the maintenance process and achieve reasonable allocation and efficient utilization of maintenance resources. 5. High-precision measurement and calibration equipmentHigh-precision measurement and calibration equipment plays a vital role in Auto Repair Equipment. These devices, such as laser aligners, electronic micrometers, etc., can provide measurement accuracy down to the micron level to ensure that the vehicle's performance after repair is optimal. By accurately measuring and adjusting the vehicle's geometric parameters, chassis balance, etc., maintenance personnel can ensure the stability and safety of the vehicle. In addition, high-precision measuring equipment can also be used to detect the degree of wear and performance changes of parts and components, providing a scientific basis for maintenance decisions. The latest technological innovations in Auto Repair Equipment include intelligent diagnostic systems, automated repair robots, 3D printing technology, Internet of Things and Internet of Vehicles technologies, and high-precision measurement and calibration equipment. These technological innovations not only improve the efficiency and accuracy of automobile maintenance, but also promote the intelligence and modernization of the entire industry. With the continuous advancement of technology and the expansion of application scenarios, it is believed that more innovative technologies and products will emerge in automobile maintenance equipment in the future, bringing broader development prospects to the automobile maintenance industry.

-

08/29 2024

Powered Hydraulic Shop Press, as an important equipment in many fields such as metal processing, automobile manufacturing and maintenance, its stability and saf...

Safe operation and maintenance of Powered Hydraulic Shop Press

Powered Hydraulic Shop Press, as an important equipment in many fields such as metal processing, automobile manufacturing and maintenance, its stability and safety are directly related to production efficiency and the life safety of operators. Therefore, when using this equipment, we must strictly abide by the safe operating procedures and perform regular maintenance and maintenance to ensure that it is in the best working condition for a long time. Importance of safe operationSafety is the premise of production. For Powered Hydraulic Shop Press, safe operation is an important basic requirement that cannot be ignored. First of all, before operation, the operator must be familiar with the performance, structure and working principle of the equipment, and operate it strictly in accordance with the operating procedures. This includes checking whether the equipment is in good condition, confirming that there are no damaged or aging parts, and wearing personal protective equipment such as safety glasses, protective gloves, earplugs, etc. At the same time, it is also necessary to clean the working area to ensure that there are no debris and obstacles to create a safe and tidy working environment. During the operation, the operator needs to pay attention to the working status of the equipment at all times, especially the changes in working pressure. It must be ensured that the working pressure does not exceed the rated pressure of the equipment to prevent equipment overload or safety accidents. In addition, avoid putting your hands or other objects into the moving parts of the equipment to prevent pinching or crushing accidents. At the same time, pay attention to the stability of the equipment to ensure that it does not shake or tilt during use. The necessity of maintenance and careMaintenance and care are the key links to extend the service life of the Powered Hydraulic Shop Press and ensure its stable performance. Regular inspection and maintenance of the equipment can timely discover and deal with potential problems and prevent failures. First of all, it is necessary to regularly check the quality of the oil to ensure that the oil is clean, free of impurities and moisture. If the oil is found to be deteriorating or seriously contaminated, it should be replaced with new oil in time, and the oil tank and oil pipe should be cleaned. At the same time, it is also necessary to replace the filter element, clean the filter, etc. to ensure the unobstructed flow of the hydraulic system. In addition to the maintenance of the Powered Hydraulic Shop Press, the mechanical parts of the equipment also need to be inspected and maintained. This includes checking the wear of the transmission parts, the looseness of the fasteners, and the lubrication of the lubricated parts. For severely worn parts, they should be replaced in time; for loose fasteners, they should be re-tightened; for parts with insufficient lubrication, an appropriate amount of lubricant should be added. In addition, the equipment needs to be cleaned and rust-proofed regularly to keep its appearance clean and its interior dry. Emergency Plan and TrainingIn addition to daily safety operation and maintenance, emergency plans and related training are also required. The emergency plan should include equipment failure handling procedures, emergency shutdown methods, and evacuation routes. Once a failure or emergency occurs, the operator should be able to quickly handle it according to the plan to ensure the safety of personnel and equipment. At the same time, regular safety training is also required for operators to improve their safety awareness and operating skills. Through training, operators can become more familiar with the performance and safe operating procedures of the equipment, reducing the occurrence of misoperation and improper operation.

English

English Español

Español Deutsch

Deutsch